As Korea’s logistics industry faces surging volumes due to the rapid growth of online commerce, many field operations still rely on repetitive and physically demanding labor. Palletizing—stacking cargo or goods onto pallets—typically involves handling 15–20kg loads and poses a high risk of musculoskeletal injuries. To address this, collaborative robot-based automation is gaining traction.

This automation case was implemented at the Ohhyun Logistics site through a collaboration between Roboe Technologies and Rainbow Robotics. The RB20-1900, with a 20kg payload and 1900mm reach—the longest in its class—was deployed to enhance operational efficiency.

Founded in 2021, Roboe Technologies is a robotics company focused on logistics automation. By conducting real-world tests and collecting field data, they develop AI-powered robots tailored for autonomous logistics tasks. Their lineup includes the Mobile Box-handling Robot (MBR), Compact Box-handling Robot (CBR), and Mobile Piece-picking Robot (MPR), which are already in use at logistics sites.

Boosting Palletizing Efficiency and Precision with the High-Payload RB20-1900

In logistics operations, palletizing is a key stage for stacking boxes of varying sizes and shapes both efficiently and securely. Traditionally, multiple workers manually lifted and placed boxes onto pallets—a process that led to accumulated fatigue, musculoskeletal disorders, and declining productivity due to repetitive strain. Manual methods also faced limitations when handling non-uniform boxes in real time.

To solve these challenges, Roboe Technologies integrated a palletizing solution equipped with Rainbow Robotics’ high-payload collaborative robot, the RB20-1900. Featuring a payload capacity of 20kg and an extended reach of 1900mm, it is the most capable model in the RB series. Designed specifically for heavy-lifting tasks, the RB20-1900 can be installed on floors, walls, or ceilings, offering excellent spatial flexibility. It also supports a unique 5-axis mode that restricts movement of the J3 joint—simplifying complex motions and reducing teaching time. Notably, when picking objects positioned close to the robot body, the arm avoids collision with the load, making it especially effective in logistics environments. This feature is exclusively offered by Rainbow Robotics among collaborative robot manufacturers and is applied to both the RB3-730 and RB20-1900 models, which are equipped with S-shaped pipes.

Realizing Smart Logistics with AI-Based Box Handling Robots

The collaborative robot RB20-1900 is integrated into Roboe Technologies’ AI-powered box handling robot, CBR (Compact Box-handling Robot). Equipped with embedded AI algorithms and a 3D vision-based smart recognition system, the robot autonomously detects the shape and position of boxes and performs optimal palletizing—achieving precise and stable stacking without human intervention. This contributes significantly to improving process efficiency and ensuring consistency in logistics quality.

The CBR features a compact footprint of 1,370 x 1,670 x 1,520 mm, making it suitable for installation in tight spaces. Its mobile platform allows flexible operation, supporting palletizing and depalletizing between two pallets placed on either side of the robot. With a maximum reach of R 1,750 mm, it can handle items transported on conveyor belts. The system enables sorted palletizing based on box size, order, or type, while real-time progress tracking and integrated safety sensors allow safe human-robot collaboration without fencing. From setup to operation and takedown, the entire process can be completed in under 10 minutes—ensuring exceptional adaptability and convenience for on-site deployment.

Improved Installation with Pneumatics Option and Integrated Software

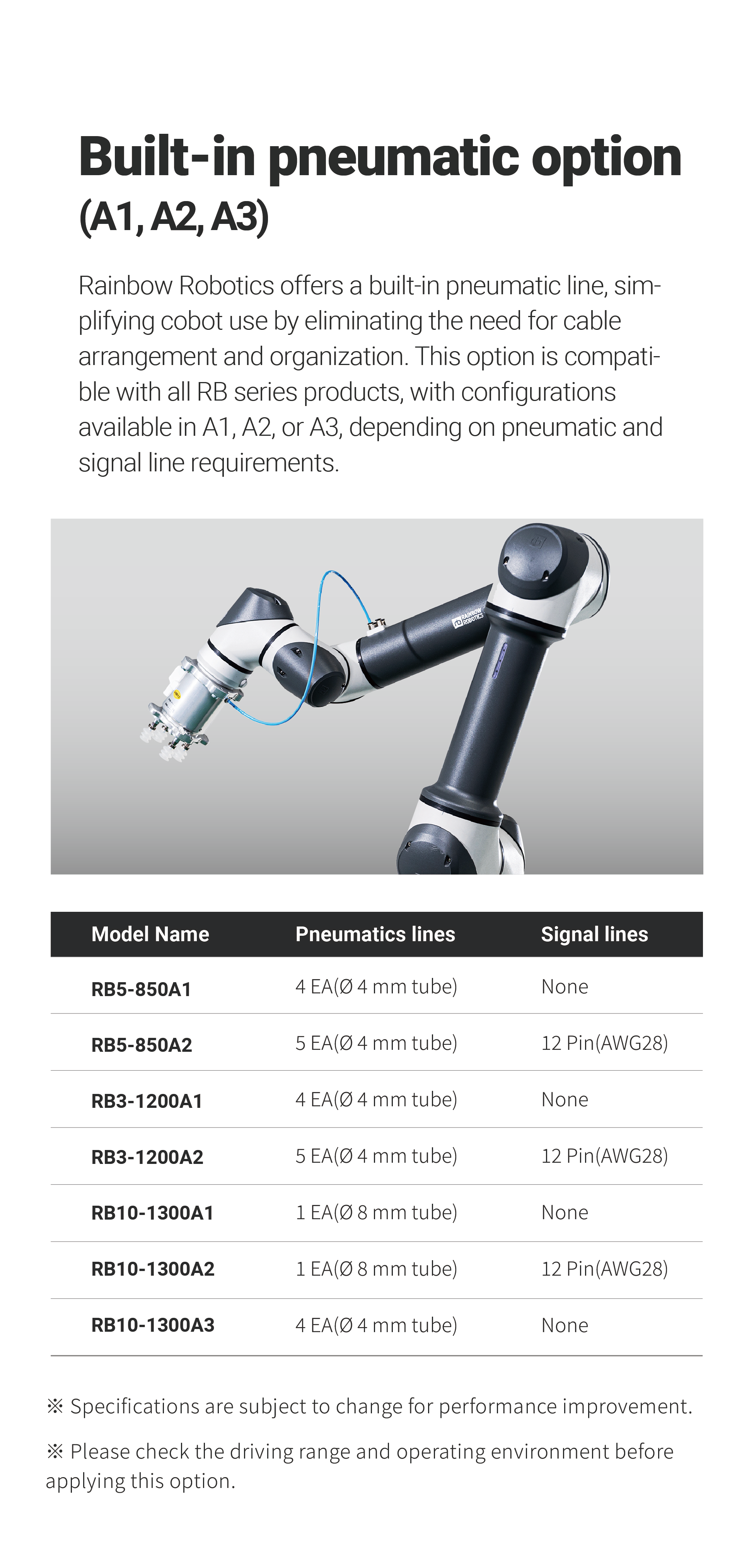

Rainbow Robotics’ RB series is the first in the collaborative robot market to offer an optional built-in pneumatic system. In this solution, the RB20-1900 with the pneumatic-integrated option was deployed, enabling direct connection of pneumatic and signal lines without cable friction or additional routing—ensuring quick integration into the production site. These features not only support smooth operation but also improve workplace safety by reducing the risk of damage or accidents.

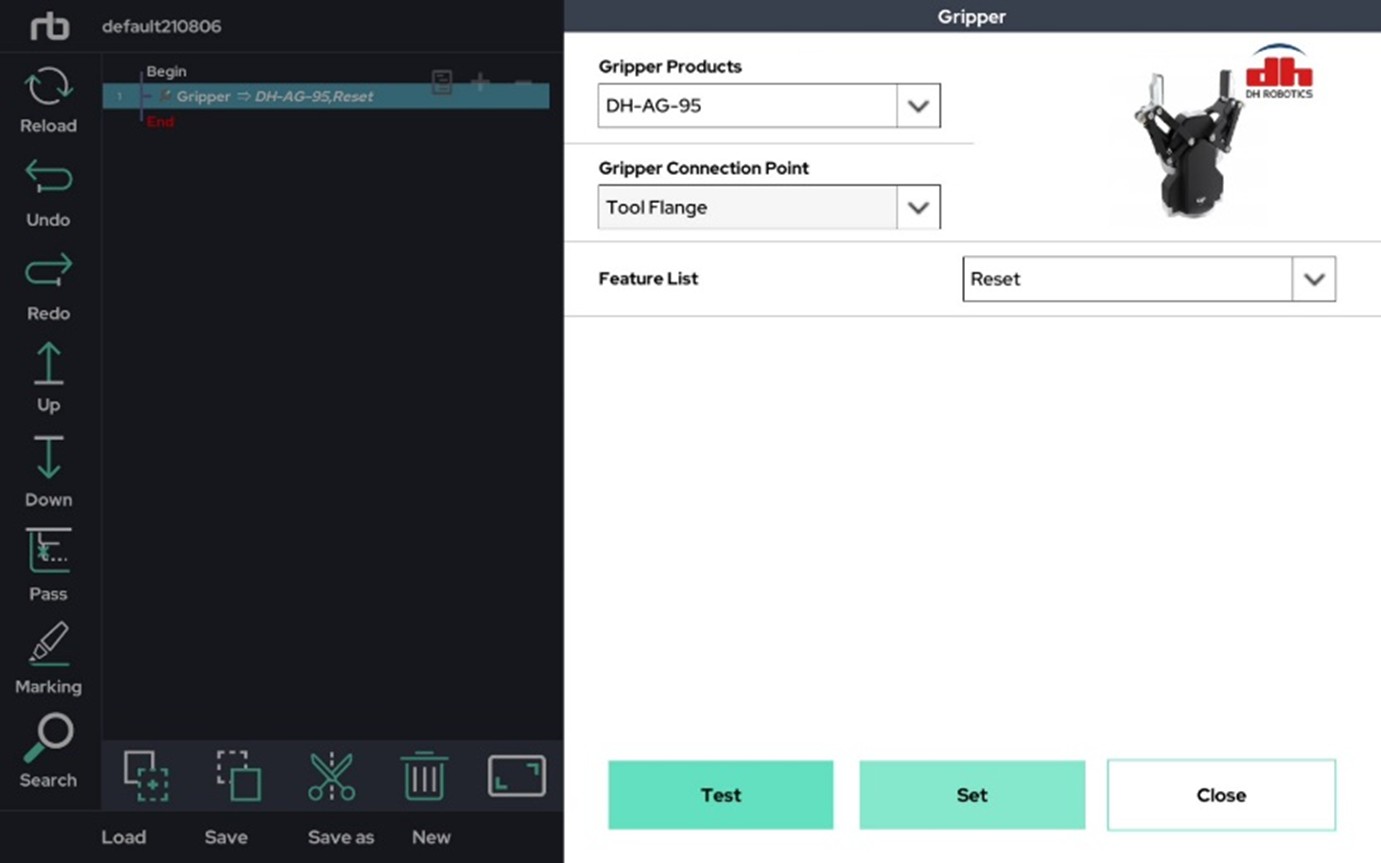

The RB series also includes built-in software that simplifies integration with a wide range of commercial grippers. Popular brands like Robotiq and OnRobot can be connected without custom programming, while complex protocols such as RS485 and Modbus RTU are easily configured. Gripper setup involves just three intuitive steps—product selection, port assignment, and function setting—making deployment fast and user-friendly.

Palletizing Automation Boosted Logistics Productivity by 150%

A logistics site that adopted the RB series collaborative robots significantly improved the efficiency of palletizing tasks, resulting in an overall productivity increase of approximately 150%. Initially, the robots were introduced in small-scale pilot operations to replace repetitive, labor-intensive loading work. As clear improvements in speed, accuracy, and reduced worker burden emerged, robot deployment was gradually expanded.

The site now operates an automated line capable of handling two pallets simultaneously, enabling uninterrupted workflow. Mixed box palletizing achieves up to 85% space utilization, significantly improving spatial efficiency. Stable load distribution also ensures consistent stacking quality. By automating repetitive tasks, the site not only addressed labor shortages but also established a predictable logistics process that enables rapid response to changing customer demands. This has positioned the facility as a leading success case in logistics automation.

Related products

Case Study

사이트 개인정보 보호 정책

㈜ 레인보우로보틱스(이하 “회사”라 함)는 「개인정보 보호법」 제30조에 따라 정보주체의 개인정보를 보호하고 이와 관련한 고충을 신속하고 원활하게 처리할 수 있도록 하기 위하여 다음과 같이 개인정보 처리방침을 수립·공개합니다.

제1조(개인정보의 처리목적)회사는 다음의 목적을 위하여 개인정보를 처리합니다. 처리하고 있는 개인정보는 다음의 목적 이외의 용도로는 이용되지 않으며 이용 목적이 변경되는 경우에는 「개인정보 보호법」 제18조에 따라 별도의 동의를 받는 등 필요한 조치를 이행할 예정입니다.

-

1.홈페이지 회원가입 및 관리

회원 가입의사 확인, 회원제 서비스 제공에 따른 본인 식별·인증, 회원자격 유지·관리, 서비스 부정이용 방지, 각종 고지·통지 목적으로 개인정보를 처리합니다. -

2.민원사무 처리

민원인의 신원 확인, 민원사항 확인, 사실조사를 위한 연락·통지, 처리결과 통보 목적으로 개인정보를 처리합니다. -

3.서비스 제공

콘텐츠 제공, 본인인증을 목적으로 개인정보를 처리합니다. -

4.마케팅 및 광고에의 활용

신규 서비스(제품) 개발 및 맞춤 서비스 제공, 이벤트 및 광고성 정보 제공 및 참여기회 제공, 서비스의 유효성 확인, 접속빈도 파악 또는 회원의 서비스 이용에 대한 통계 등을 목적으로 개인정보를 처리합니다.

- ①회사는 법령에 따른 개인정보 보유·이용기간 또는 정보주체로부터 개인정보를 수집 시에 동의받은 개인정보 보유·이용기간 내에서 개인정보를 처리·보유합니다.

- ②각각의 개인정보 처리 및 보유 기간은 다음과 같습니다.

| 보존항목 | 운영근거 | 보유기간 |

|---|---|---|

| 홈페이지 회원가입 및 관리와 관련한 개인정보 | 정보주체 동의 | 3년 |

| 개인정보 열람 등 요구 처리 사용자 정보 | 개인정보보호법 제35조-제39조 | 3년 |

| 문의와 관련한 개인정보 | 정보주체 동의 | 1년 |

| 서비스 방문 기록 | 통신비밀보호법 | 1년 |

- ①정보주체는 회사에 대해 언제든지 개인정보 열람·정정·삭제·처리정지 요구 등의 권리를 행사할 수 있습니다.

- ②제1항에 따른 권리 행사는 회사에 대해 「개인정보 보호법」 시행령 제41조제1항에 따라 서면, 전자우편, 모사전송(FAX) 등을 통하여 하실 수 있으며 회사는 이에 대해 지체 없이 조치하겠습니다.

- ③제1항에 따른 권리 행사는 정보주체의 법정대리인이나 위임을 받은 자 등 대리인을 통하여 하실 수 있습니다. 이 경우 “개인정보 처리 방법에 관한 고시(제2020-7호)” 별지 제11호 서식에 따른 위임장을 제출하셔야 합니다.

- ④개인정보 열람 및 처리정지 요구는 「개인정보 보호법」 제35조 제4항, 제37조 제2항에 의하여 정보주체의 권리가 제한될 수 있습니다.

- ⑤개인정보의 정정 및 삭제 요구는 다른 법령에서 그 개인정보가 수집 대상으로 명시되어 있는 경우에는 그 삭제를 요구할 수 없습니다.

- ⑥회사는 정보주체 권리에 따른 열람의 요구, 정정·삭제의 요구, 처리정지의 요구 시 열람 등 요구를 한 자가 본인이거나 정당한 대리인인지를 확인합니다.

-

1.채용/구매/제품/기타문의

이름, 이메일 등 기재정보 -

2.인터넷 서비스 이용과정에서 아래 개인정보 항목이 자동으로 생성되어 수집될 수 있습니다.

IP주소, 쿠키, MAC주소, 서비스 이용기록, 방문기록, 불량이용기록 등

- ①회사는 개인정보 보유기간의 경과, 처리목적 달성 등 개인정보가 불필요하게 되었을 때에는 지체없이 해당 개인정보를 파기합니다.

- ②개인정보 파기의 절차 및 방법은 다음과 같습니다.

-

1.파기절차

회사는 파기 사유가 발생한 개인정보를 선정하고, 회사의 개인정보 보호책임자의 승인을 받아 개인정보를 파기합니다. -

2.파기방법

전자적 파일 형태의 정보는 기록을 재생할 수 없는 기술적 방법을 사용합니다.

종이에 출력된 개인정보는 분쇄기로 분쇄하거나 소각을 통하여 파기합니다

회사는 개인정보의 안전성 확보를 위해 다음과 같은 조치를 취하고 있습니다.

- 1.관리적 조치: 개인정보 취급 직원의 최소화 및 교육, 내부관리계획 수립 및 시행 등

- 2.기술적 조치: 해킹 등에 대비한 기술적 대책, 개인정보의 암호화, 개인정보에 대한 접근 제한, 문서보안을 위한 잠금장치 사용 등

- ①회사는 이용자에게 개별적인 맞춤서비스를 제공하기 위해 이용정보를 저장하고 수시로 불러오는 ‘쿠키(cookie)’를 사용합니다.

-

②쿠키는 웹사이트를 운영하는데 이용되는 서버(http)가 이용자의 컴퓨터 브라우저에게 보내는 소량의 정보이며 이용자들의 PC 컴퓨터내의 하드디스크에 저장되기도 합니다.

- 가.쿠키의 사용 목적 : 이용자가 방문한 각 서비스와 웹 사이트들에 대한 방문 및 이용형태, 인기 검색어, 보안접속 여부, 등을 파악하여 이용자에게 최적화된 정보 제공을 위해 사용됩니다.

- 나.쿠키의 설치•운영 및 거부 : 웹브라우저 상단의 도구>인터넷 옵션>개인정보 메뉴의 옵션 설정을 통해 쿠키 저장을 거부 할 수 있습니다.

- 다.쿠키 저장을 거부할 경우 맞춤형 서비스 이용에 어려움이 발생할 수 있습니다.

- ①회사는 개인정보 처리에 관한 업무를 총괄해서 책임지고, 개인정보 처리와 관련한 정보주체의 불만처리 및 피해구제 등을 위하여 아래와 같이 개인정보 보호책임자를 지정하고 있습니다.

성명: 이정호 대표이사

► 개인정보 보호 담당부서

부서명: 마케팅팀

담당자: 김유림

연락처: 전화) 042-719-8104, 팩스) 042-719-8071, 이메일) yr.kim@rainbow-robotics.com

- ①정보주체는 회사의 서비스(또는 사업)을 이용하시면서 발생한 모든 개인정보 보호 관련 문의, 불만처리, 피해구제 등에 관한 사항을 개인정보 보호책임자 및 담당부서로 문의하실 수 있습니다. 레인보우로보틱스 은(는) 정보주체의 문의에 대해 지체 없이 답변 및 처리해드릴 것입니다.

정보주체는 「개인정보 보호법」 제35조에 따른 개인정보의 열람 청구를 아래의 부서에 할 수 있습니다. 회사는 정보주체의 개인정보 열람청구가 신속하게 처리되도록 노력하겠습니다.

► 개인정보 열람청구 접수·처리 부서

부서명: 마케팅팀

담당자: 김유림

연락처: 전화) 042-719-8104, 팩스) 042-719-8071, 이메일) yr.kim@rainbow-robotics.com

정보주체는 개인정보침해로 인한 구제를 받기 위하여 개인정보분쟁조정위원회, 한국인터넷진흥원 개인정보침해신고센터 등에 분쟁해결이나 상담 등을 신청할 수 있습니다. 이 밖에 기타 개인정보침해의 신고, 상담에 대하여는 아래의 기관에 문의하시기 바랍니다.

- 1.개인정보분쟁조정위원회 : (국번없이) 1833-6972 (www.kopico.go.kr)

- 2.개인정보침해신고센터 : (국번없이) 118 (privacy.kisa.or.kr)

- 3.대검찰청 : (국번없이) 1301 (www.spo.go.kr)

- 4.경찰청 : (국번없이) 182 (ecrm.cyber.go.kr)

「개인정보보호법」제35조(개인정보의 열람), 제36조(개인정보의 정정·삭제), 제37조(개인정보의 처리정지 등)의 규정에 의한 요구에 대 하여 공공기관의 장이 행한 처분 또는 부작위로 인하여 권리 또는 이익의 침해를 받은 자는 행정심판법이 정하는 바에 따라 행정심판을 청구할 수 있습니다.

※ 행정심판에 대해 자세한 사항은 중앙행정심판위원회(www.simpan.go.kr) 홈페이지를 참고하시기 바랍니다.

제13조(개인정보 처리방침 변경)- ①이 개인정보처리방침은 2023년 02월 10일부터 적용됩니다.

사이트 이용약관

레인보우로보틱스(이하 “회사”라 함)가 운영하는 “사용자 공간” 서비스 이용에 있어서 게시, 제공, 검색, 손해배상 및 면책에 대해서는 아래의 규정이 적용됩니다.

제1조(목적)이 약관은 레인보우로보틱스가 운영하는 사용자 공간에서 제공하는 인터넷 관련 서비스(이하 “서비스”라 함)를 이용함에 있어 사용자 공간과 이용자의 권리·의무 및 책임사항을 규정하는데 그 목적이 있습니다.

제2조(정의)- 1.“사용자 공간”이란 고객 및 협력사(Partner)가 레인보우로보틱스 협동로봇 관련 다양한 기술적 정보에 접근하고, 회원간 정보 공유가 가능한 웹사이트 플랫폼을 말합니다.

- 2.“이용자”란 “사용자 공간”에 접속하여 이 약관에 따라 회사가 제공하는 서비스를 받는 회원을 말합니다.

- 3.‘회원’이라 함은 회사에 개인정보를 제공하여 회원등록을 한 자로서, 회사의 정보를 지속적으로 제공받으며 회사가 제공하는 서비스를 이용할 수 있는 자를 말합니다.

- 1.회사는 이 약관의 내용과 상호 및 대표자 성명, 영업소 소재지 주소, 전화번호, 전자우편주소, 개인정보관리책임자 등을 이용자가 쉽게 알 수 있도록 사용자 공간 초기 서비스화면(전면)에 게시합니다. 다만, 약관의 내용은 이용자가 연결화면을 통하여 볼 수 있도록 할 수 있습니다.

- 2.회사는 이용자가 약관에 동의하기에 앞서 약관에 정해져 있는 내용 중 중요한 내용을 이용자가 이해할 수 있도록 별도의 연결화면을 제공하여 이용자의 확인을 구하여야 합니다.

- 3.회사는 「약관의 규제에 관한 법률」, 「전자문서 및 전자거래기본법」, 「전자서명법」, 「정보통신망 이용촉진 및 정보보호 등에 관한 법률」, 「소비자기본법」 등 관련 법을 위배하지 않는 범위에서 이 약관을 개정할 수 있습니다.

- 4.회사가 약관을 개정할 경우에는 적용일자 및 개정사유를 명시하여 현행약관과 함께 사용자 공간(약칭)의 초기화면에 그 적용일자 7일 이전부터 적용일자 전일까지 공지합니다. 다만, 이용자에게 불리하게 약관내용을 변경하는 경우에는 최소한 30일 이상의 사전 유예기간을 두고 공지합니다. 이 경우 회사는 개정 전 내용과 개정 후 내용을 명확하게 비교하여 이용자가 알기 쉽도록 표시합니다.

- 5.회사가 약관을 개정할 경우에는 그 개정약관은 그 적용일자 이후에 체결되는 계약에만 적용되고 그 이전에 이미 체결된 계약에 대해서는 개정 전의 약관조항이 그대로 적용됩니다. 다만 이미 계약을 체결한 이용자가 개정약관 조항의 적용을 받기를 원하는 뜻을 제3항에 의한 개정약관의 공지기간 내에 회사에 송신하여 회사의 동의를 받은 경우에는 개정약관 조항이 적용됩니다.

-

1.“사용자 공간”은 다음과 같은 업무를 수행합니다.

- ①협동로봇에 대한 기술정보 제공

- ②회원간 정보 공유가 가능한 포럼 사이트 운영

- ③기타 사용자 공간이 정하는 업무

- 2.“사용자 공간”은 제품의 품절 또는 기술적 사양의 변경 등의 경우에는 장차 체결되는 계약에 의해 제공할 재화 또는 용역의 내용을 변경할 수 있습니다. 이 경우에는 변경된 재화 또는 용역의 내용 및 제공일자를 명시하여 현재의 재화 또는 용역의 내용을 게시한 곳에 즉시 공지합니다.

- 3.“사용자 공간”이 제공하기로 이용자와 계약을 체결한 서비스의 내용을 재화 등의 품절 또는 기술적 사양의 변경 등의 사유로 변경할 경우에는 그 사유를 이용자에게 통지 가능한 주소로 즉시 통지합니다.

- 4.전항의 경우 “회사”는 이로 인하여 이용자가 입은 손해를 배상합니다. 다만, “사용자 공간”이 고의 또는 과실이 없음을 입증하는 경우에는 그러하지 아니합니다.

- 1.“사용자 공간”은 컴퓨터 등 정보통신설비의 보수점검․교체 및 고장, 통신의 두절 등의 사유가 발생한 경우에는 서비스의 제공을 일시적으로 중단할 수 있습니다.

- 1.이용자는 “사용자 공간”이 정한 가입 양식에 따라 회원정보를 기입한 후 이 약관에 동의한다는 의사표시를 함으로서 회원가입을 신청합니다.

-

2.“사용자 공간”은 제1항과 같이 회원으로 가입할 것을 신청한 이용자 중 다음 각 호에 해당하지 않는 한 회원으로 등록합니다.

- ①가입신청자가 이 약관 제7조제3항에 의하여 이전에 회원자격을 상실한 적이 있는 경우, 다만 제7조제3항에 의한 회원자격 상실 후 3년이 경과한 자로서 “사용자 공간”의 회원재가입 승낙을 얻은 경우에는 예외로 한다.

- ②등록 내용에 허위, 기재누락, 오기가 있는 경우

- ③기타 회원으로 등록하는 것이 “사용자 공간”의 기술상 현저히 지장이 있다고 판단되는 경우

- 3.회원가입계약의 성립 시기는 “사용자 공간”의 승낙이 회원에게 도달한 시점으로 합니다.

- 4.회원은 회원가입 시 등록한 사항에 변경이 있는 경우, 상당한 기간 이내에 “사용자 공간”에 대하여 회원정보 수정 등의 방법으로 그 변경사항을 알려야 합니다.

- 1.회원은 “회사”에 언제든지 탈퇴를 요청할 수 있으며 “회사”는 즉시 회원탈퇴를 처리합니다.

-

2.회원이 다음 각 호의 사유에 해당하는 경우, “회사”는 회원자격을 제한 및 정지시킬 수 있습니다.

- ①가입 신청 시에 허위 내용을 등록한 경우

- ②다른 사람의 “사용자 공간” 이용을 방해하거나 그 정보를 도용하는 등 질서를 위협하는 경우

- ③“사용자 공간”을 이용하여 법령 또는 이 약관이 금지하거나 공서양속에 반하는 행위를 하는 경우

- ④“회사”가 회원 자격을 제한․정지시킨 후, 동일한 행위가 2회 이상 반복되거나 30일 이내에 그 사유가 시정되지 아니하는 경우 “회사”는 회원자격을 상실 시킬 수 있습니다.

- ⑤“회사”가 회원자격을 상실시키는 경우에는 회원등록을 말소합니다. 이 경우 회원에게 이를 통지하고, 회원등록 말소 전에 최소한 30일 이상의 기간을 정하여 소명할 기회를 부여합니다.

- 1.“회사”가 회원에 대한 통지를 하는 경우, 회원이 “회사”와 미리 약정하여 지정한 전자우편 주소로 할 수 있습니다.

- 2.“회사”는 불특정다수 회원에 대한 통지의 경우 1주일 이상 “사용자 공간” 게시판에 게시함으로써 개별 통지에 갈음할 수 있습니다. 다만, 회원 본인과 관련하여 중대한 영향을 미치는 사항에 대하여는 개별통지를 합니다.

- 1.“회사”가 제3자에게 이용자의 개인정보를 제공할 필요가 있는 경우 1) 개인정보를 제공받는 자, 2)개인정보를 제공받는 자의 개인정보 이용목적, 3) 제공하는 개인정보의 항목, 4) 개인정보를 제공받는 자의 개인정보 보유 및 이용기간을 구매자에게 알리고 동의를 받아야 합니다. (동의를 받은 사항이 변경되는 경우에도 같습니다.)

- 2.“사용자 공간”이 제3자에게 구매자의 개인정보를 취급할 수 있도록 업무를 위탁하는 경우에는 1) 개인정보 취급위탁을 받는 자, 2) 개인정보 취급위탁을 하는 업무의 내용을 구매자에게 알리고 동의를 받아야 합니다. (동의를 받은 사항이 변경되는 경우에도 같습니다.) 다만, 서비스제공에 관한 계약이행을 위해 필요하고 구매자의 편의증진과 관련된 경우에는 「정보통신망 이용촉진 및 정보보호 등에 관한 법률」에서 정하고 있는 방법으로 개인정보 취급방침을 통해 알림으로써 고지절차와 동의절차를 거치지 않아도 됩니다.

- 1.“회사”는 이용자의 개인정보 수집 시 서비스제공을 위하여 필요한 범위에서 최소한의 개인정보를 수집합니다.

- 2.“회사”는 회원가입 시 구매계약이행에 필요한 정보를 미리 수집하지 않습니다. 다만, 관련 법령상 의무이행을 위하여 구매계약 이전에 본인확인이 필요한 경우로서 최소한의 특정 개인정보를 수집하는 경우에는 그러하지 아니합니다.

- 3.“회사”는 이용자의 개인정보를 수집·이용하는 때에는 당해 이용자에게 그 목적을 고지하고 동의를 받습니다.

- 4.“회사”는 수집된 개인정보를 목적 외의 용도로 이용할 수 없으며, 새로운 이용목적이 발생한 경우 또는 제3자에게 제공하는 경우에는 이용·제공단계에서 당해 이용자에게 그 목적을 고지하고 동의를 받습니다. 다만, 관련 법령에 달리 정함이 있는 경우에는 예외로 합니다.

- 5.“회사”가 제2항과 제3항에 의해 이용자의 동의를 받아야 하는 경우에는 개인정보관리 책임자의 신원(소속, 성명 및 전화번호, 기타 연락처), 정보의 수집목적 및 이용목적, 제3자에 대한 정보제공 관련사항(제공받은 자, 제공목적 및 제공할 정보의 내용) 등 「정보통신망 이용촉진 및 정보보호 등에 관한 법률」 제22조제2항이 규정한 사항을 미리 명시하거나 고지해야 하며 이용자는 언제든지 이 동의를 철회할 수 있습니다.

- 6.“회사”는 개인정보 보호를 위하여 이용자의 개인정보를 취급하는 자를 최소한으로 제한하여야 하며 이용자의 개인정보의 분실, 도난, 유출, 동의 없는 제3자 제공, 변조 등으로 인한 이용자의 손해에 대하여 모든 책임을 집니다.

- 7.“회사” 또는 그로부터 개인정보를 제공받은 제3자는 개인정보의 수집목적 또는 제공받은 목적을 달성한 때에는 당해 개인정보를 지체 없이 파기합니다.

- 8.“회사”는 개인정보의 수집·이용·제공에 관한 동의 란을 미리 선택한 것으로 설정해두지 않습니다. 또한 개인정보의 수집·이용·제공에 관한 이용자의 동의거절 시 제한되는 서비스를 구체적으로 명시하고, 필수수집항목이 아닌 개인정보의 수집·이용·제공에 관한 이용자의 동의 거절을 이유로 회원가입 등 서비스 제공을 제한하거나 거절하지 않습니다.

- 1.“사용자 공간”은 법령과 이 약관이 금지하거나 공서양속에 반하는 행위를 하지 않으며 이 약관이 정하는 바에 따라 지속적이고, 안정적으로 재화․용역을 제공하는데 최선을 다하여야 합니다.

- 2.“사용자 공간”은 이용자가 안전하게 인터넷 서비스를 이용할 수 있도록 이용자의 개인정보(신용정보 포함)보호를 위한 보안 시스템을 갖추어야 합니다.

- 3.“사용자 공간”이 상품이나 용역에 대하여 「표시․광고의 공정화에 관한 법률」 제3조 소정의 부당한 표시․광고행위를 함으로써 이용자가 손해를 입은 때에는 이를 배상할 책임을 집니다.

- 4.“사용자 공간”은 이용자가 원하지 않는 영리목적의 광고성 전자우편을 발송하지 않습니다.

- 1.제17조의 경우를 제외한 ID와 비밀번호에 관한 관리책임은 회원에게 있습니다.

- 2.회원은 자신의 ID 및 비밀번호를 제3자에게 이용하게 해서는 안됩니다.

- 3.회원이 자신의 ID 및 비밀번호를 도난당하거나 제3자가 사용하고 있음을 인지한 경우에는 바로 “회사”에 통보하고 “회사”의 안내가 있는 경우에는 그에 따라야 합니다.

- 1.신청 또는 변경 시 허위 내용의 등록

- 2.타인의 정보 도용

- 3.“회사”가 정한 정보 이외의 정보(컴퓨터 프로그램 등) 등의 송신 또는 게시

- 4.기타 제3자의 저작권 등 지적재산권에 대한 침해

- 5.기타 제3자의 명예를 손상시키거나 업무를 방해하는 행위

- 6.외설 또는 폭력적인 메시지, 화상, 음성, 기타 공서양속에 반하는 정보를 사용자 공간에 공개 또는 게시하는 행위

- 1.회사가 작성한 “사용자 공간” 저작물에 대한 저작권 기타 지적재산권은 ”회사“에 귀속합니다.

- 2.이용자는 “사용자 공간”을 이용함으로써 얻은 정보 중 “회사”에게 지적재산권이 귀속된 정보를 “회사”의 사전 승낙 없이 복제, 송신, 출판, 배포, 방송 기타 방법에 의하여 영리목적으로 이용하거나 제3자에게 이용하게 하여서는 안됩니다.

- 3.“회사”는 약정에 따라 이용자에게 귀속된 저작권을 사용하는 경우 당해 이용자에게 통보하여야 합니다.